Construction :

We have studied that the ordinary 3 phase squirrel cage motor has low starting torque. This is due to its low rotor resistance, But if rotor bars are made of high resistance then starting torque will increase but at the same time there will be more rotor Cu-loss, and the efficiency of the motor will decrease.The Double cage motor is so developed that it overcomes the above difficulty and gives good starting torque with good efficiency.

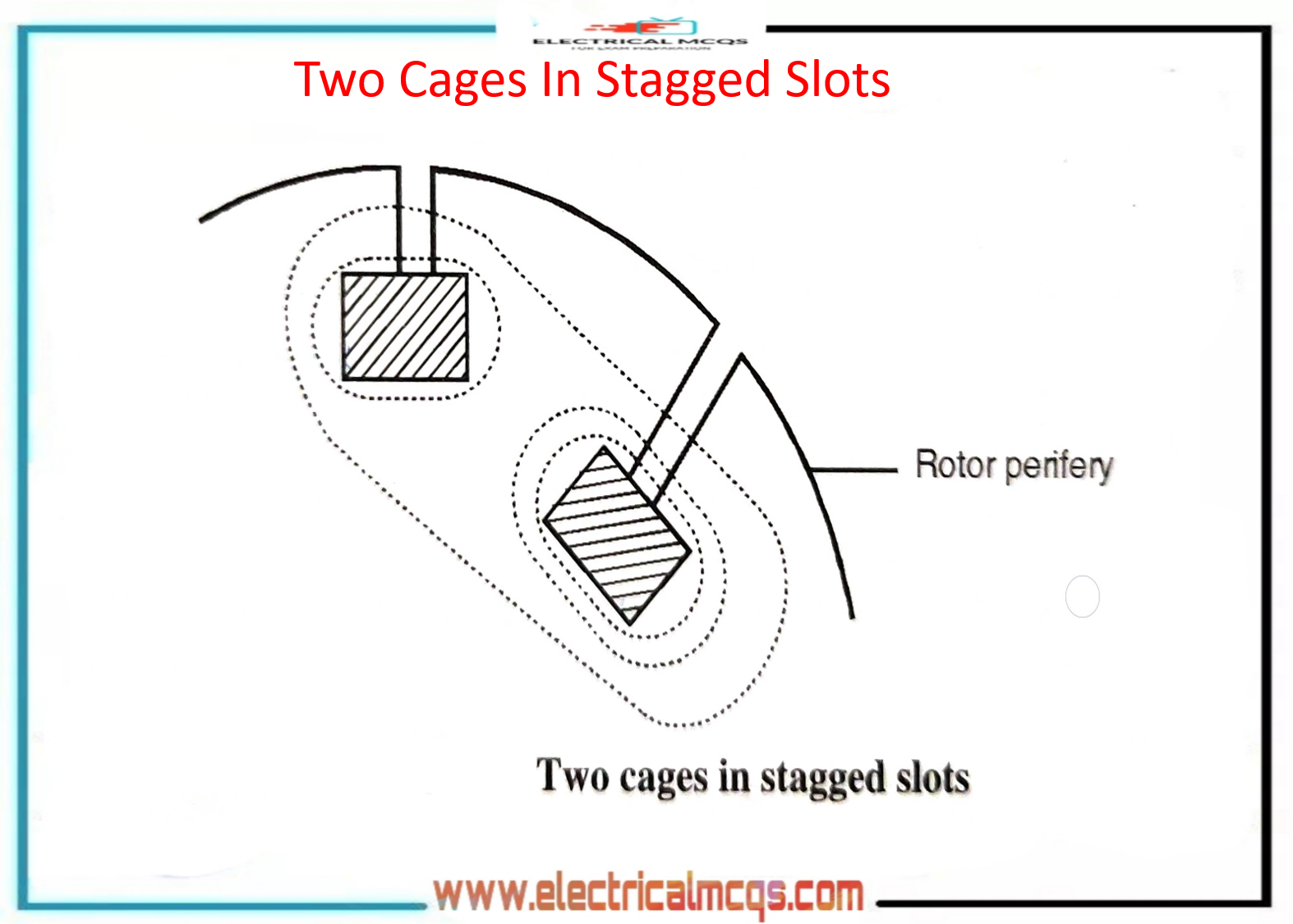

The rotor slot and the rotor conductor has a modified peculiar shape as shown in the following diagram.

It has two cages. The Upper (outer) cage near the surface of the rotor periphery, is called as the starting cage. The conductor in this starting cage is made of high resistance iron or brass material.

The lower (inner) is located deeply. This cage is called as the running cage and it has the conductors made of low resistance copper.

Working of Double Cage Squirrel Cage Induction Motor:

At starting the slip speed and hence the frequency of the induced current is high. (May be equal to supply frequency).

The lower cage of copper forms more inductive circuit than the upper brass cage this is because the copper cage is completely surrounded by the iron structure of the rotor. Thus the reactance due to higher rotor frequency at start is more.

At start the impedance of the lower cage is more in comparison with the upper cage and hence the lower cage accepts small current and more part passes through high resistance outer cage.

The starting torque is improved. Starting torque is about 200 to 250% of the full load torque and starting Currents is 4 to 5 times the full load current.

But under the running conditions, as the motor gains speed, the frequency of the rotor current becomes very small so that the impedance of the lower cage is very less in comparison with the upper cage and the lower cage copper conductors take a great share of current and gives a reasonable good running torque.

Torque Slip Characteristic:

The pullout torque of the double cage motor is smaller than that of the ordinary squirrel cage motor. This is because two cages produce their maximum torques at two different speeds.

In some designs, the two cages are placed into stagged slots as shown in the following Fig. along with the flux linking.

Overall construction and shape of the double cage motor is similar as the ordinary squirrel cage motor having stator and rotor as main parts.

It is noticed in this type of double cage motor that in normal running conditions both cages carry current, this increases the overall power rating of the motor as compared with the ordinary squirrel cage motor.

Advantages of Double Cage Motor:

1. Higher starting torque than plain motors.2. The inner cage reduces the full load power factor.

3. Outer cage increases Cu, loss due to higher resistance.

4. Efficiency reduces

5. Cost is much more due to the special construction of double cages.